Stainless steel profiles are true all-rounders in the home – robust, versatile and adding that certain something to any room. But even the best materials can be affected by flash rust. Let's explore together why this happens, how you can recognise it and, above all, how you can best care for your stainless steel profiles.

Stainless steel – an overview

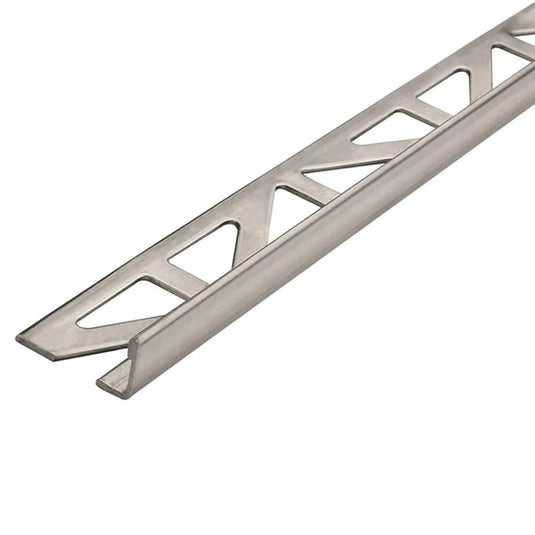

Stainless steel is more than just a material – it is a promise of quality and versatility. As an alloy of iron, chromium and nickel, stainless steel is known for its outstanding durability and attractive appearance. But what actually makes stainless steel so special? The outstanding feature of stainless steel is its rust resistance. Thanks to the protective oxide layer that forms on its surface, stainless steel resists the effects of water, air and other environmental factors. This corrosion resistance makes it a preferred choice in humid environments such as bathrooms and kitchens. Its ability to adapt to a wide variety of conditions makes it a long-lasting companion. Whether indoors or outdoors, stainless steel profiles withstand the stresses of everyday use while maintaining their integrity.

Have you noticed brown spots on the stainless steel surface? Rust? How can that be, when we've just listed the valuable properties of stainless steel? Don't worry – the brown spots may not be rust. If there are no bulges or other deformations on the material, it is most likely flash rust.

Flush rust: Rust's little brother

Flash rust is one such issue. It is caused by tiny metal particles that settle on the surface. The problem can occur if stainless steel is stored improperly, for example near black steel. There is also a risk of this happening during angle grinder work on construction sites due to flying sparks. In such cases, metal particles can be carried by air or water and settle in recesses, edges and notches. This causes these metal particles to start rusting – but not the stainless steel itself. If the removal of flash rust is neglected, the formation of the protective passive layer can be prevented and the stainless steel is exposed to the rusting process. Therefore, thorough and regular cleaning of the tile profile is essential. Unlike real rust, it only affects the outer layer and does not penetrate the material. This makes it less dramatic – but prevention is still important.

Typical causes of flash rust

Why can stainless steel develop flash rust despite its robustness? Common reasons are:

- Contamination with black steel dust – e.g. from neighbouring storage or processing.

- Use of tools that have previously been in contact with unalloyed steel.

- Incorrect flex discs during assembly – these can damage surfaces.

- Inadequate cleaning after installation – residues such as adhesive or silicone promote corrosion.

- Condensation and poor ventilation also promote the formation of flash rust.

Removing surface rust

Keep your stainless steel profiles in good condition! In most cases, surface rust can be removed easily. Special cleaners or cleaning pastes work well here. A clean cloth, fine sandpaper or a polishing attachment for your drill can help with stubborn areas. Please always test all cleaning methods on an inconspicuous area first.

Preventing surface rust

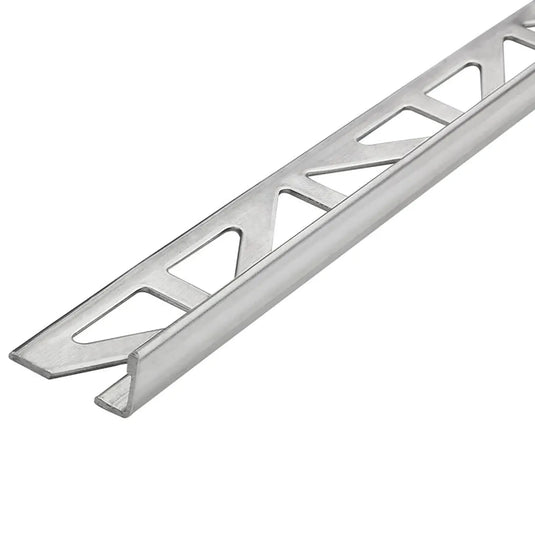

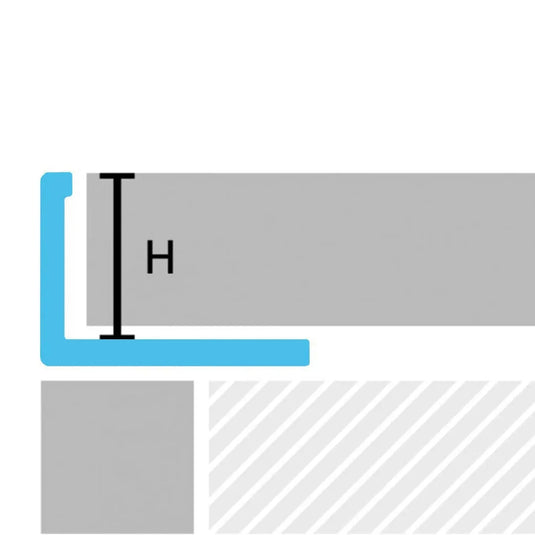

The best defence is good care – because flash rust does not just appear out of nowhere. Clean stainless steel profiles thoroughly and regularly after installation. Keep tools and working environments free of iron. For particularly demanding situations, V4A stainless steel is the more resilient choice, e.g. our V4A stainless steel straight edge tile trim.