Bathroom waterproofing is a critical component in the construction process that is often underestimated. Mistakes in this area can result in long-term damage and high costs. In this blog post, we take a look at the most common mistakes made when waterproofing bathrooms and give you tips on how to avoid them.

The 5 most common mistakes made when sealing:

1. Inadequate preparation of the substrate:

The substrate is not thoroughly cleaned or leveled before the waterproofing is applied. Dust, dirt and unevenness can impair the adhesion of the waterproofing materials.

2. Lack of sealing in critical areas:

Not all critical areas, such as corners, connections to plumbing installations and penetrations, are carefully sealed. These places are particularly susceptible to water leaks.

3. Insufficient overlap of the sealing sheets:

The waterproofing membranes are not overlapped sufficiently or are installed incorrectly, which leads to leaks.

4. Using the wrong sealing material:

Not every waterproofing material is suitable for every substrate or application. Using the wrong material can lead to ineffective waterproofing.

5. Neglecting drying and curing times:

The sealing materials are not completely dried or cured before further work begins, which can lead to damage.

Would you like to be a little more specific? No problem, we will go into more detail on each point.

Problem:

A carefully prepared substrate is the foundation of any successful waterproofing job in the bathroom. Unfortunately, this step is often underestimated, which can lead to significant problems. Inadequate cleaning and leveling of the substrate are the main culprits. Dust, dirt and even the smallest unevenness on the surface can significantly impair the adhesion of the waterproofing materials. In addition, grease and oil residues can negatively affect the effectiveness of the waterproofing by weakening the bond between the waterproofing material and the surface. Cracks and holes in the substrate provide potential entry points for water, which endangers the integrity of the entire waterproofing measure.

Solution:

Careful preparation of the substrate is essential for long-lasting and effective waterproofing of your bathroom. Start by thoroughly cleaning the surface to remove all contaminants such as dust, dirt, and grease and oil residues. The type of cleaning depends on the substrate and can range from simple sweeping to the use of special cleaning agents. Then it is important to ensure that the substrate is completely dry. Moisture can affect the adhesion of the waterproofing materials and should therefore be eliminated before starting the waterproofing work. Next, it is all about leveling out unevenness. Use suitable fillers and leveling compounds to repair cracks and holes and create a flat surface. An even surface is essential for effective application of the waterproofing materials and helps to minimize the risk of water pooling under the waterproofing. Finally, applying your primer can significantly improve the adhesion of the waterproofing materials to the substrate. This is especially true for absorbent materials such as concrete, where a primer promotes a strong bond between the substrate and the waterproofing.

Problem:

There are critical areas in every bathroom that are particularly susceptible to water damage. These include corners, connections to plumbing fixtures such as sinks, toilets and showers, and passages for pipes or cables. These places are particularly at risk as they are often where materials meet or movements are concentrated in the building. Unfortunately, they are often overlooked or not adequately secured during waterproofing, which can lead to costly water damage later on.

Solution:

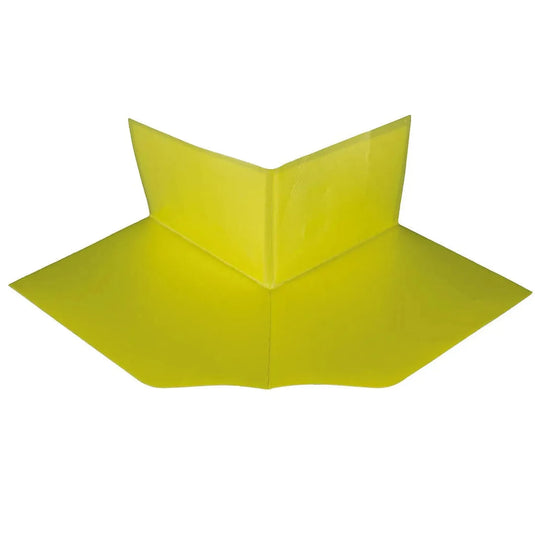

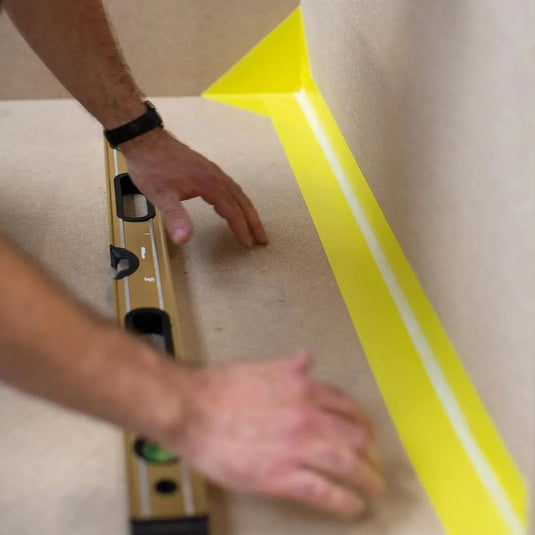

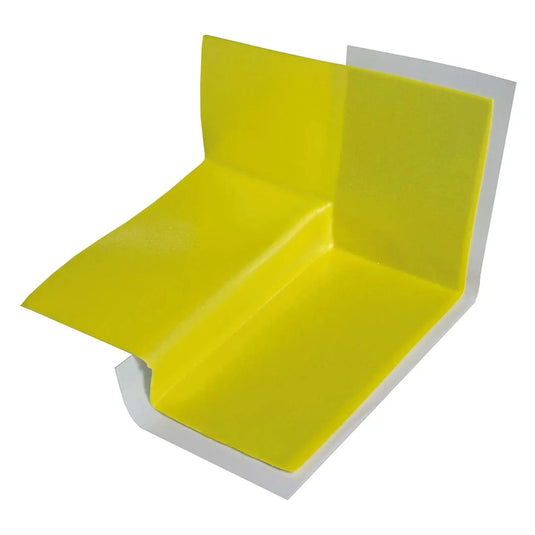

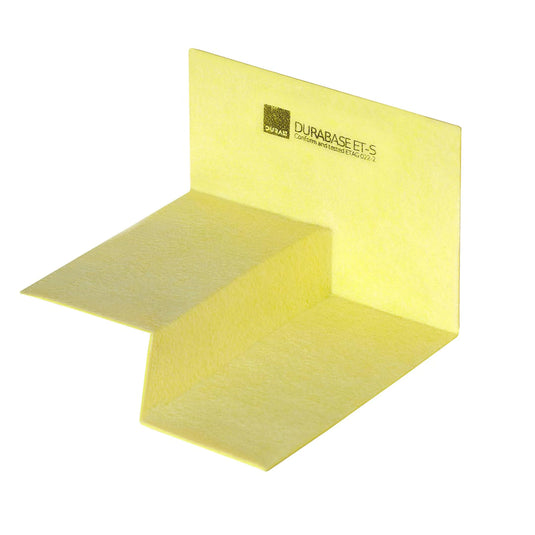

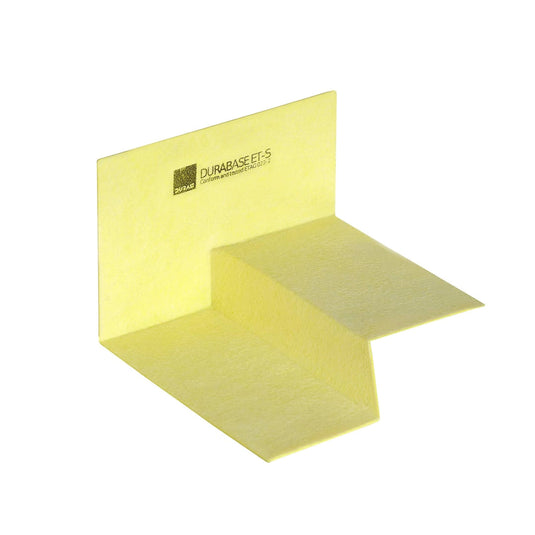

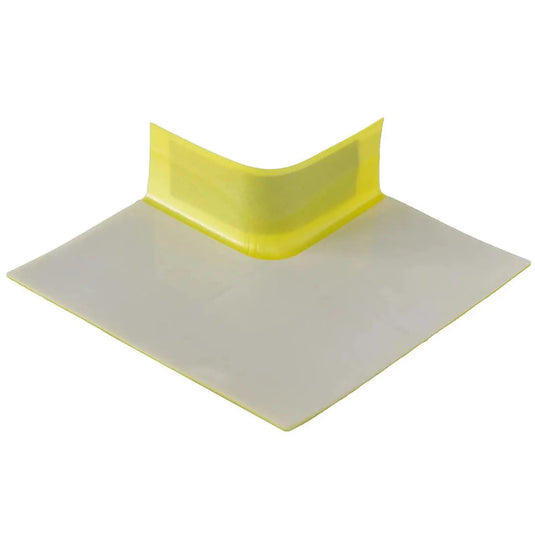

In order to effectively protect the critical areas in your bathroom, it is important to use specially developed sealing elements. Suitable sealing tapes, sleeves and molded parts ensure a seamless seal even in complicated areas such as corners, connections to sanitary elements and penetrations. Sealing tapes, e.g. the DURAL sealing tape ET-S, are flexible and can therefore be easily incorporated into corners and overlaps. Sealing tapes reinforce these areas and offer additional protection against water ingress. Sleeves, e.g. the sealing sleeves are particularly indispensable for penetrations such as pipes or cables. They enclose the penetration and create a watertight connection between the pipe and the surface to be sealed. Moulded parts such as the ET-S sealing corners offer optimum protection for corners and special connections, such as shower trays or bathtubs. They adapt to the geometric characteristics of these areas and thus prevent water from penetrating.

Problem:

A common mistake when installing waterproofing membranes in bathrooms is not overlapping the membranes properly. This mistake can lead to serious problems, as even small leaks can compromise the entire waterproofing. Water always takes the path of least resistance. If waterproofing membranes are not overlapped correctly, weak spots are created through which moisture can penetrate and cause significant damage over time.

Solution:

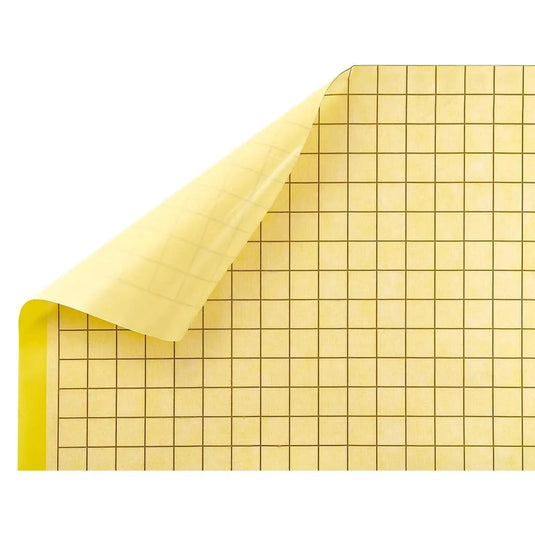

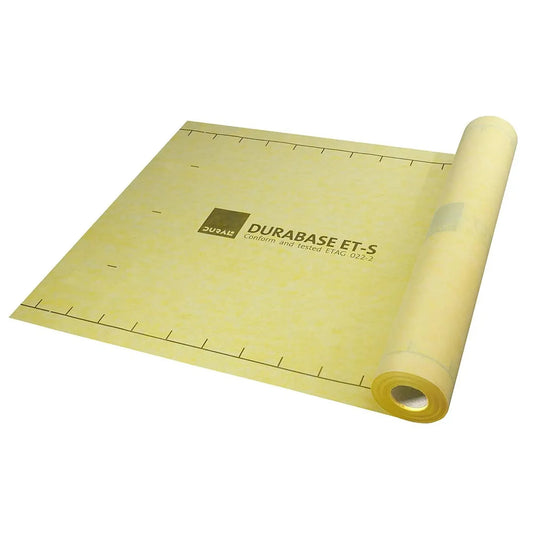

To avoid leaks, it is crucial that sealing sheets, e.g. our DURAL ET-S sealing sheet, are not only laid correctly, but also provided with sufficient overlap. An overlap of at least 10 cm ensures that there are no gaps between the sheets through which water could penetrate. In addition, the correct alignment of the sheets must be observed so that the overlaps effectively protect against the flow of water.

Problem:

A critical step in waterproofing a bathroom that is often underestimated is choosing the right waterproofing material. Different substrates and applications have different waterproofing requirements. A material that adheres well to one substrate does not automatically mean it will work equally well on another. Using the wrong waterproofing material can cause problems ranging from inadequate adhesion to complete waterproofing failure, ultimately compromising the structure of the bathroom.

Solution:

To ensure that your bathroom waterproofing is effective and long-lasting, a thorough examination of the substrate is essential. Different materials such as concrete, wood, plasterboard or tiles react differently to waterproofing materials and therefore have specific waterproofing requirements. This means that the perfect waterproofing material for concrete is not necessarily the best choice for wooden substrates.

Equally important is the assessment of the moisture load in the bathroom. Areas that are regularly exposed to high levels of moisture, such as showers and tubs, require more robust waterproofing solutions compared to other areas of the bathroom that are less exposed to moisture. Pay particular attention to the suitability of the material for different substrates and applications, as well as specific properties such as flexibility, water vapor permeability and chemical resistance. In addition, the manufacturer's recommendations are of great importance. They are based on extensive testing and experience and provide reliable guidance on the performance and suitability of the material for specific applications.